About Ethanol from damaged food grain

Low Carbon, Low Cost and Made in India

Using Damaged Grains To Make Ethanol: Oil Retailers Await Norms -

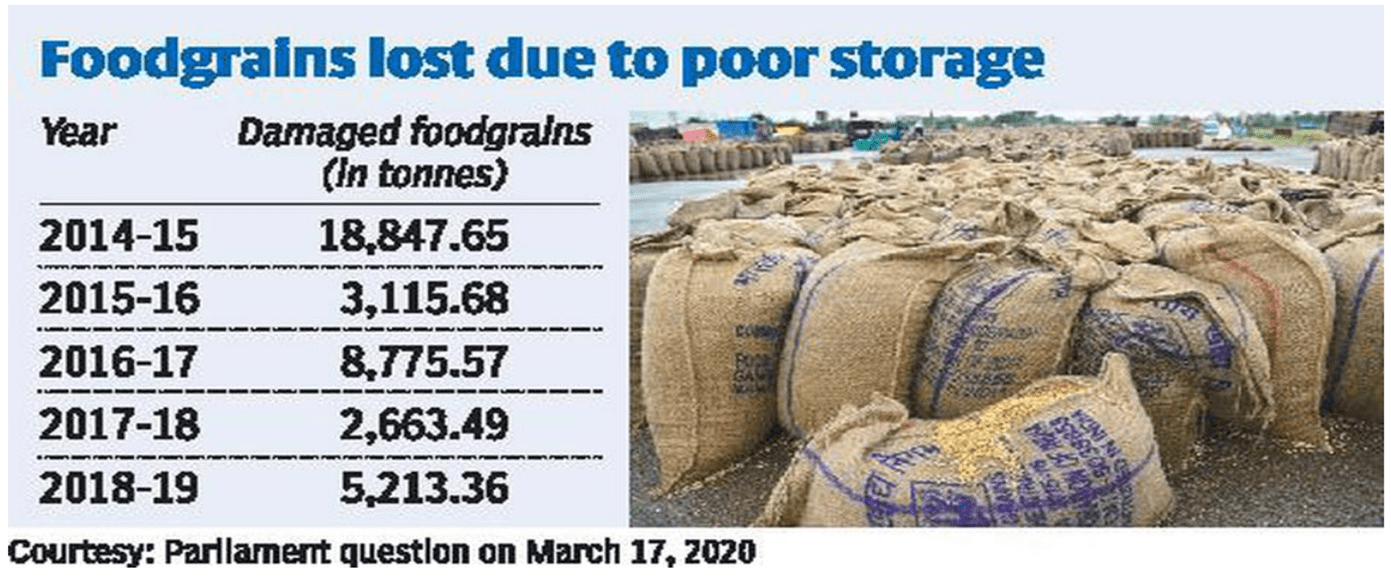

Food Grains Lost Due To Poor Storage

| Sr.No. | Year | Damaged Foodgrains(In tonnes) |

|---|---|---|

| 1 | 2014-15 | 18,847.65 |

| 2 | 2015-16 | 3,115.68 |

| 3 | 2016-17 | 8,775.57 |

| 4 | 2017-18 | 2,663.49 |

| 5 | 2018-19 | 5,213.36 |

Courtesy: Parllament question on Mrch 17,2020

Why Choose Biofuel

Using Damaged Grains To Make Ethanol: Oil Retailers Await Norms -

Saving Economy

Public oil marketing companies saved 433.6 crore litres of petrol due to ethanol blending. If E20 was available across the country, it would save Rs 50,000 crore in foreign exchange costs.

Saving the Planet

On average, ethanol reduces greenhouse gas emissions by 46% when compared to petroleum. INEPL is on track to double the reduction in greenhouse gas emissions from our ethanol by 2025, resulting in a fuel energy product that is 90% lower in greenhouse gas emissions than petroleum.

Supporting Rural Economies

INEPL purchases the grain grown within a 100 Km radius of our facility. The ethanol industry provides payment of over ₹40,600 crore to rural environments—while giving local farmers a reliable place to bring their grain while increasing demand for their product.

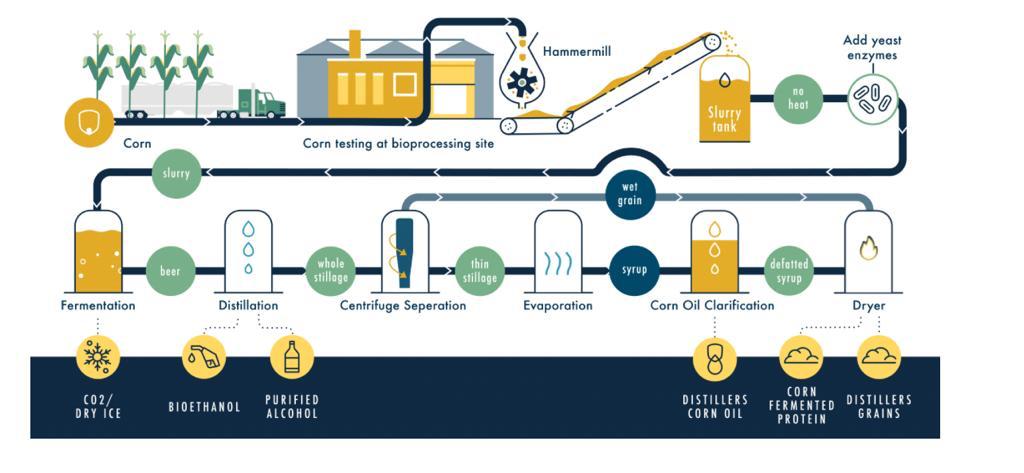

The Fermentation Process

Indo Nuclear Energy ethanol is produced through the natural process of fermentation, enhanced by cutting-edge enzymatic and technological developments, to efficiently convert the starch in grain to fermentable sugar. Because we are committed to utilizing every part of of grain, we also produce Distillers Dried Grains With Solubles (DDGS), Distillers Corn Oil (DCO), and Pure Biogenic Carbon Dioxide.

Fermentation Co-Products

We are committed to utilizing every part of each grain; we innovate what others view as waste to provide low-carbon solutions. Indo Nuclear Energy, a bio-ethanol facility, uses the natural process of photosynthesis and fermentation to create ethanol and three co-products: Distillers Dried Grain with Solubles (DDGS), Distillers Corn Oil, and Pure Biogenic Carbon Dioxide.

Distillers Dried Grain with Solubles (DDGS)

BIPS Pure Biogenic Carbon Dioxide

At INEPL, tons of pure, biogenic carbon dioxide is captured during fermentation each year. This extremely pure CO2 captured through the fermentation process enables INEPL to provide low and even negative carbon-intensity feed an fuel solutions.

A Look Ahead: Ethanol as a Platform Molecule